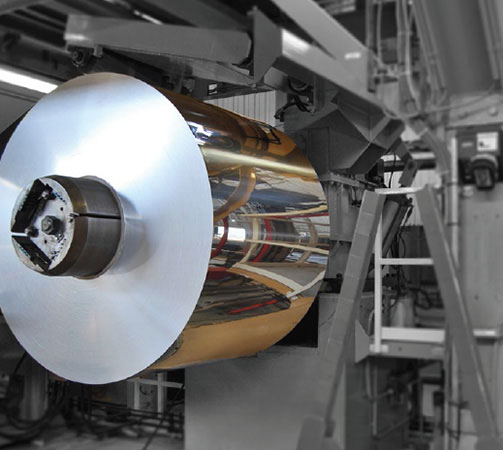

According to the alloy model to classify ,our color coated aluminium strip has the four series:1000 series,3000 series,5000 series,8000 series.

(1) 1060 1100 Color Coated Aluminium Coil

1060 color coated aluminum coil sheet is low strength and pure aluminium, has good deep drawing quality, therefore it is widely used for making cap, closure, can, cosmetic cover etc. 1060 aluminum coated coil sheet is good for anodizing and bright surface, so it is ideal aluminium to make mirror sheet, color coated mirror sheet coil.

1100 color coated aluminum coil sheet is pure aluminium, with excellent forming characteristics, 1100 H14 aluminum coated coil strip is normally used for making rain gutter, 1100 H12 O aluminum coated coil strip is normally used for making fin stock, heat exchanger fins.

Alloy:1060 1100

Temper:HO,H12,H14,H16,H18,H22,H24,H26

Thickness:0.2mm-6.0mm

Width:80mm-2300mm

Standard production:ASTM-B-209M,BS EN 485-2,BS EN 573-3,GB/T3880-2008

MOQ:5 tons per size

Mother coil:DC or CC

ID:76mm,152mm,408mm,508mm

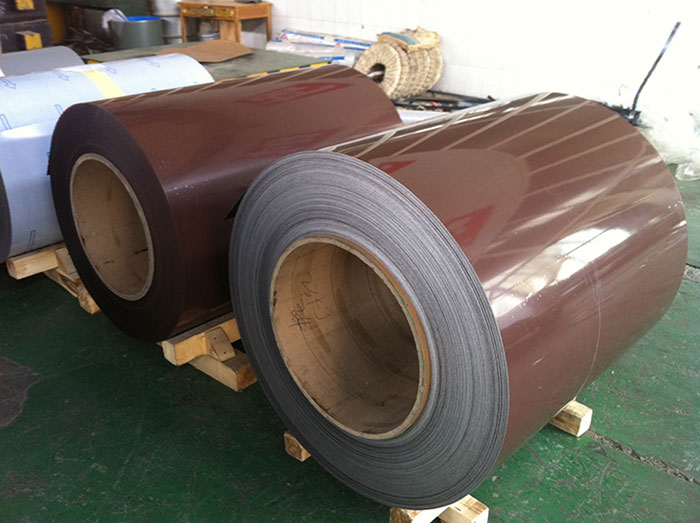

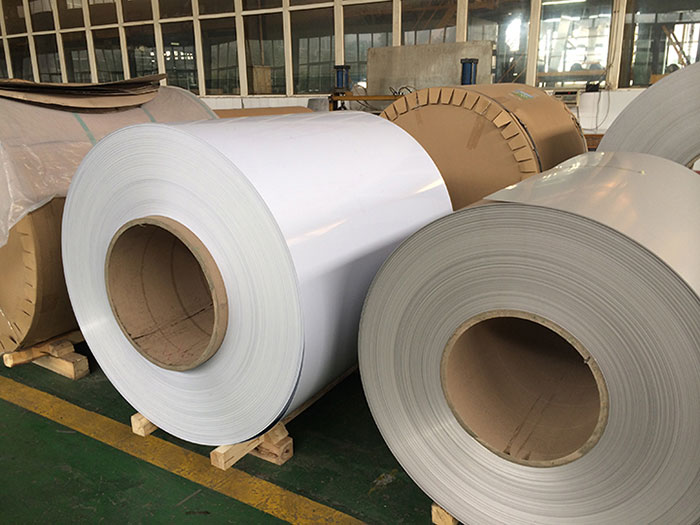

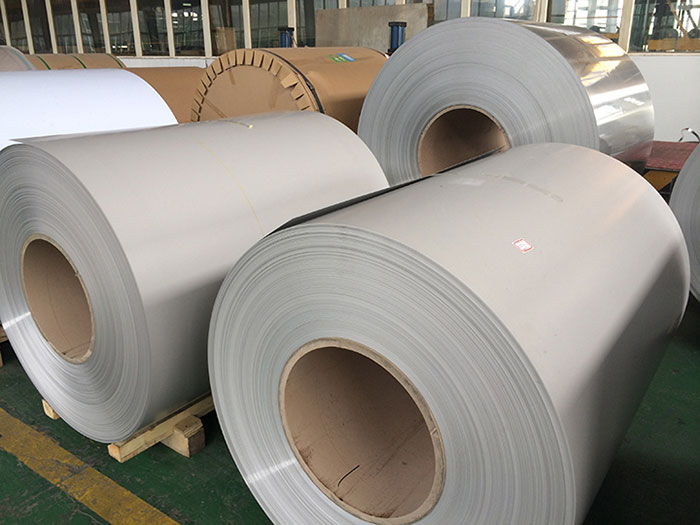

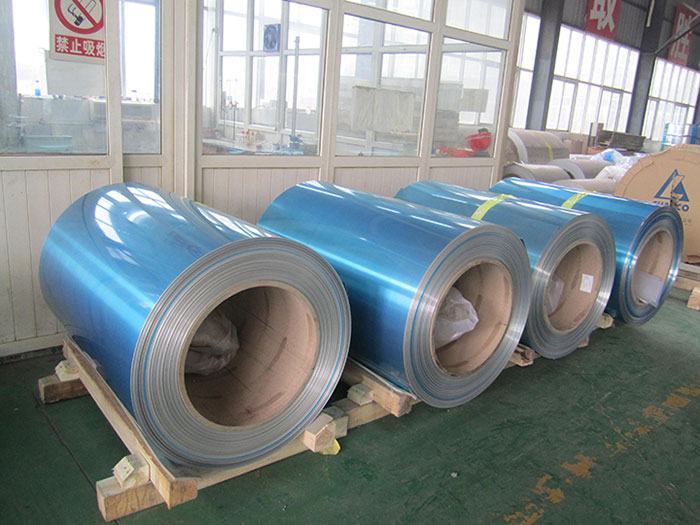

Surface:Color Coated, Many kinds of Color

Package:Export standard package with wooden pallet

Package way:Eye to sky or eye to wall

Delivery time:within 30days

Origin:Zhengzhou,China

Certificate: Mill Test Certificate,Certificate of origin:Form A,Form E,CO

Payment: T/T

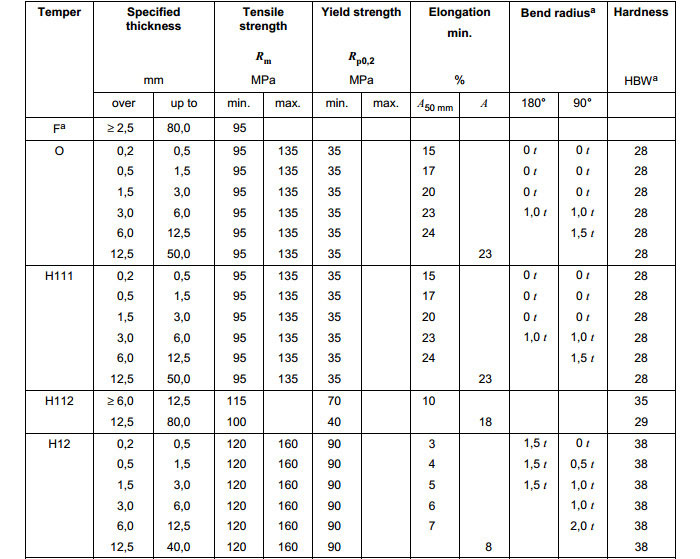

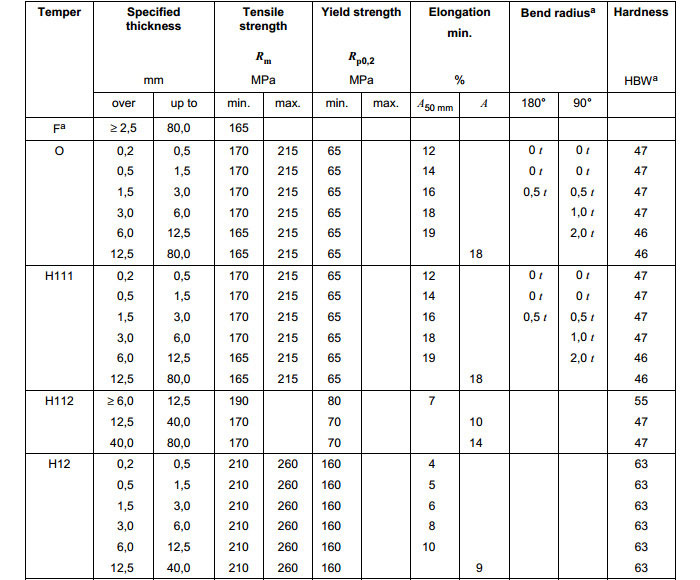

Mechanical Properties – 1100 Color Coated Aluminium Coil Strip

| Thickness(mm) | Tensile strength(Mpa) | Yield strength(Mpa) | Elongtion(%) |

| 0.2-0.3 | 110-145 | 95 | 1 |

| 0.301-0.5 | 110-145 | 95 | 2 |

| 0.51-1.5 | 110-145 | 95 | 3 |

| 1.51-4.0 | 110-145 | 95 |

5 |

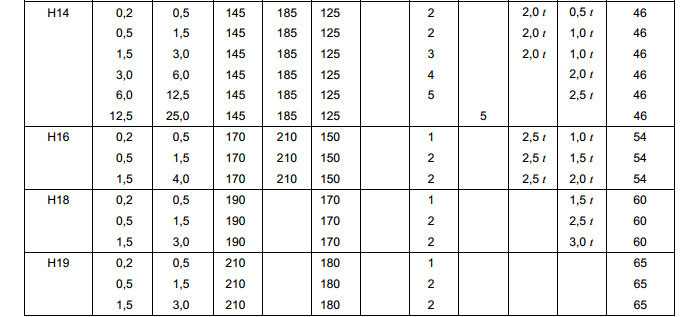

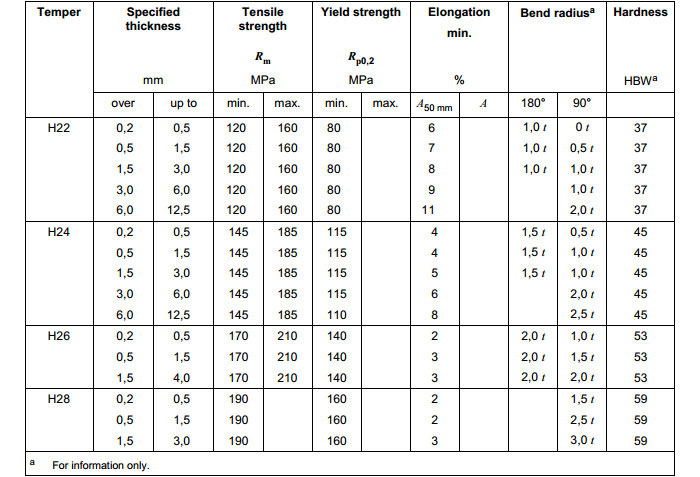

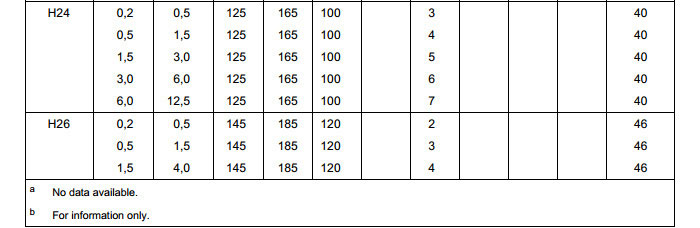

Mechanical Properties – EN AW-1060 Color Coated Aluminium Coil Strip

| Alloy |

Supplier Temper |

Testing Temper |

Thickness (mm) |

Tensile Strength Rm/Mpa |

Extension Strength Rp0.2/MPa |

Elongation after Break | Bending Radius | ||

| A50mm | A5.55e | ||||||||

| Not less than | |||||||||

| O | O | > 0.2 – 0.30 | 60 – 100 | 15 | 15 | – | – | ||

| > 0.3 – 0.50 | 18 | – | – | ||||||

| > 0.5 – 1.50 | 23 | – | – | ||||||

| > 1.5 – 6.0 | 25 | – | – | ||||||

| > 6.0 – 80.0 | 25 | 22 | – | ||||||

| H12 | H12 | > 0.5 – 1.50 | 80 – 120 | 60 | 6 | – | – | ||

| H22 | H22 | > 1.5 – 6.0 | 12 | – | – | ||||

|

H14 H24 |

H14 H24 |

> 0.2 – 0.3 | 95 – 135 | 70 | 1 | – | – | ||

| > 0.3 – 0.5 | 2 | – | – | ||||||

| > 0.5 – 0.8 | 2 | – | – | ||||||

| > 0.8 – 1.5 | 4 | – | – | ||||||

| > 1.5 – 3.0 | 6 | – | – | ||||||

| > 3.0 – 6.0 | 10 | – | – | ||||||

|

H16 H26 |

H16 H26 |

> 0.2 – 0.3 | 110 – 155 | 75 | 1 | – | – | ||

| > 0.3 – 0.5 | 2 | – | – | ||||||

| > 0.5 – 0.8 | 2 | – | – | ||||||

| > 0.8 – 1.5 | 3 | – | – | ||||||

| > 1.5 – 4.0 | 5 | – | – | ||||||

| H18 | H18 | > 0.2 – 0.3 | 125 | 85 | 1 | – | – | ||

| > 0.3 – 0.5 | 2 | – | – | ||||||

| > 0.5 – 1.5 | 3 | – | – | ||||||

| > 1.5 – 3.0 | 4 | – | – | ||||||

| H112 | H112 | > 4.5 – 6.0 | 75 | – | 10 | – | – | ||

| > 6.0 – 12.5 | 75 | 10 | – | – | |||||

| > 12.5 – 40.0 | 70 | – | 18 | – | |||||

| > 40.0 – 80.0 | 60 | – | 22 | – | |||||

| F | – | > 2.5 – 150 | – | – | |||||

| TOLERANCE | |||||

| Major Brand | A1060(O) | ||||

| Thickness | 0.2-0.4 | 0.4-0.8 | 0.9-1.1 | 1.2-1.6 | 1.8-2.0 |

| tolerance | ±0.01 | ±0.015 | ±0.02 | ±0.025 | ±0.03 |

| Width | <100 | 100-200 | 201-500 | 501-1250 | >1250 |

| tolerance | ±0.1 | ±0.2 | ±0.2 | ±1 | ±2 |

| BURR AND COLLAPSE | |||||

| The width of aluminum belt | burr’s height | collapsed side’s height | |||

| <0.2 | 0.01 | ≥0.05-0.1 | |||

| 0.2-1.0 | 0.015 | ||||

| 1.1-1.5 | 0.02 | ||||

| >1.6 | 0.03 | ||||

| MECHANICAL PROPERTY | |||||

| U.T.S: 60-95N/mm2 | Elongation: >25% | ||||

| Density in 20°C :2.703kg/dm3 | Max.resistance in 20°C:≤0.02825Ωmm2/m | ||||

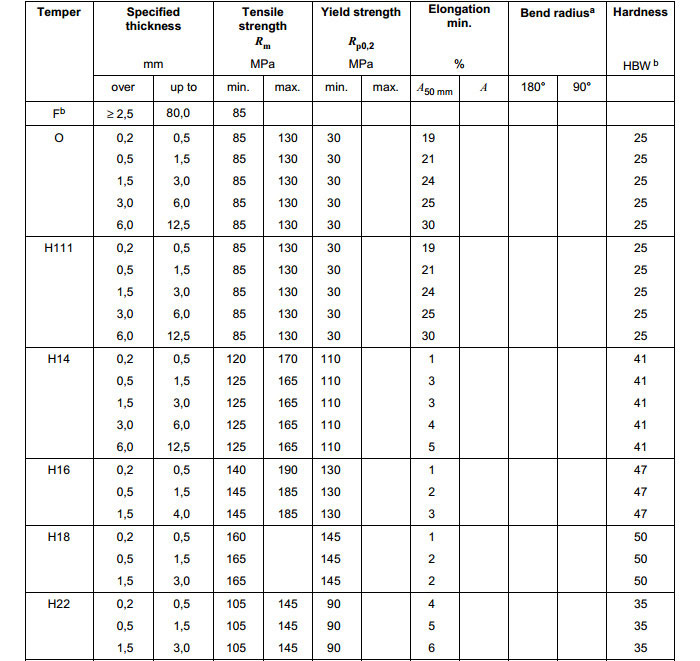

(2) 3003 3105 Coated Aluminum Coil

3003 color coated aluminum coil sheet is an important alloy in China, price cheaper than 3105, and almost same as 1100、1060、1070 etc alloy, but has medium strength with good resistance to atmospheric corrosion, and very good weldability as well as good cold formability. It has better mechanical properties, especially at elevated temperatures than the 1000 series alloys. Therefore

3003 aluminum coated coil sheet is widely used for building industry, such as roofing and sidings, ceilings, corrugated sheets, good for insulation of heating and cooling.

3105 color coated aluminum coil sheet is an essentially 98% pure aluminium alloy with minor additions for strengths, because it has manganese, its corrosion resistance is very good, and also its strength is greater than 1000 series alloys, but its price is almost same as 1000 series alloys, therefor it is widely used for making roofing.

Alloy:AA3003 3105

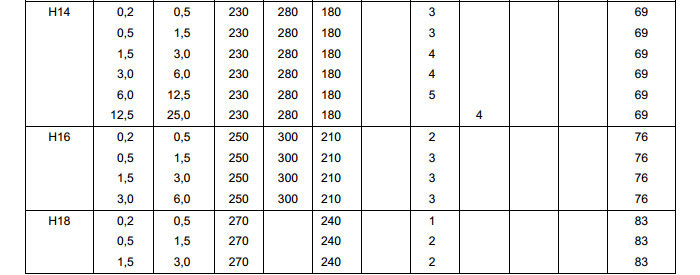

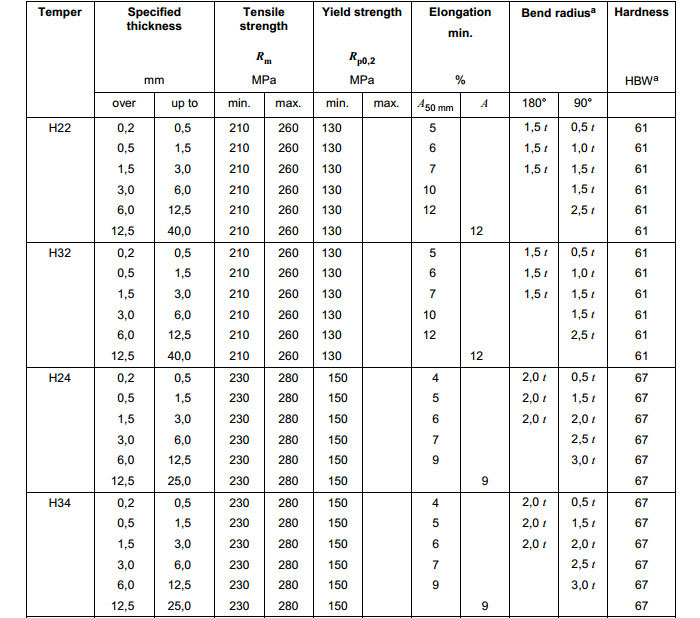

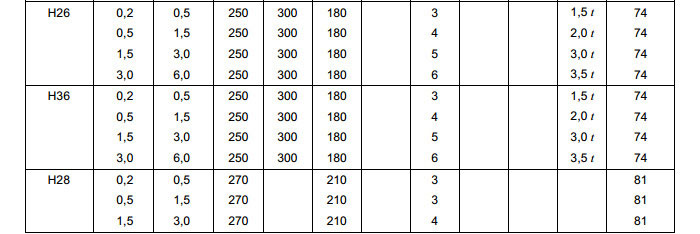

Temper:HO,H12,H14,H16,H18,H22,H24,H26,H28

Thickness:0.2mm-6.0mm

Width:80mm-2300mm

Length:100-11000mm

Standard production:ASTM-B-209M,BS EN 485-2,BS EN 573-3,GB/T3880-2008

MOQ:5 tons per size

Mother coil:DC or CC

Weight:about 0.3-2.5mts per pallet

Surface:Color Coated, Many kinds of Color

Package:Export standard package with wooden pallet

Delivery time:within 30days

Origin:Zhengzhou,China

Certificate: Mill Test Certificate,Certificate of origin:Form A,Form E,CO

Regular size:1.0*1219*2438,2.0*1220*2440,3.0*1200*2400,3.0*1200*3600,2.5*1250*2500,

3.0*1500*3000,2.0*1500*3600

Specification – 3003 Color Coated Aluminium Coil Strip

Product Name 3003 Aluminum Coil Strip

Thickness(mm) 0.0065-150mm

Width(mm) 25mm-2200mm

Packing Export standard, covering with brown paper and plastic film then packed with wooden case/pallet, eye to wall or eye to sky

(3) 5052 5454 5754 Coated Aluminum Coil

5052 color coated aluminum coil sheet has very good corrosion resistance to seawater and marine and industrial atmosphere, it also has very good weldability and good cold formability, so it is widely used in industrial field.

5454 color coated aluminum coil sheet is widely used in European and American market, because its good bending and excellent weldability, formability and corrosion property, they are widely used for tank body, dry bulk trailers and dump bodies.

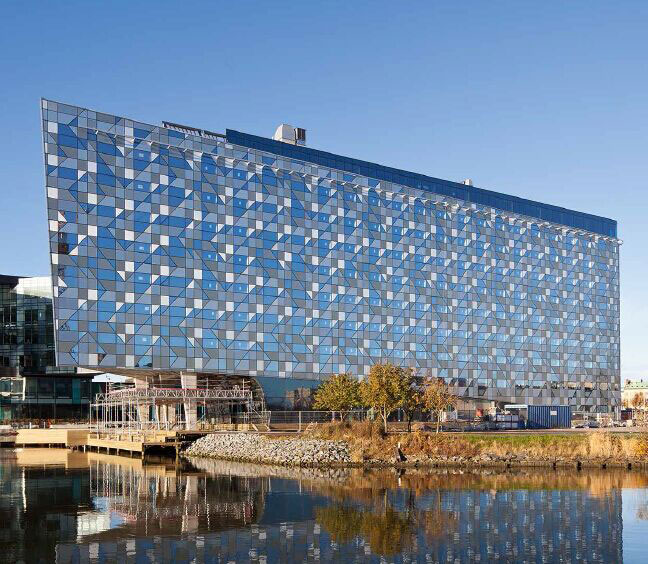

5754 color coated aluminum coil sheet is normally used for building exterior, normally with temper H34, thickness above 2mm, because aluminum 5754 has excellent corrosion resistance and higher strength: it especially resist to water and industrially polluted atmospheres; and it has higher strength than 5052, this high strength make 5754 highly suitable for flooring and curtain wall application.

| Product Name | 5052 5454 5754 Aluminum Coil Strip |

| Thickness(mm) | 0.5-150mm |

| Width(mm) | 25mm-2200mm |

| Packing |

Export standard, covering with brown paper and plastic film then packed with wooden case/pallet, eye to wall or eye to sky |

Alloy:5052 5454 5754

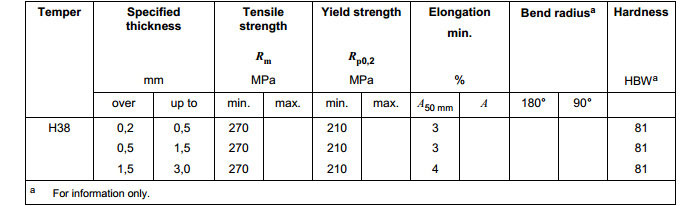

Temper:H32,H34,H38,H111,H112,H114,HO

Mother coil:DC

Thickness:0.5-150mm

Width:100-2300mm

MOQ:5ton per size

Surface:Color Coated, Many kinds of Color

Weigth:about 2mt per pallet

Package:export standard package,wooden pallet with fumigation

Package way:Eye to sky or Eye to wall

Delivery time:about 30days after receiving the deposit

Payment:TT

Trading terms:FOB,CIF,CFR

Product standard:GBT,JIS ,EN,ASTM

We can supply the Form E, Form A,CO and so on

(4) 8011 8079 Coated Aluminum Coil

8011 color coated aluminum coil sheet is most popular commercial alloys in packaging industry, 8011 H14 color coated aluminum coil sheet normally used for making PP cap, ROPP cap, aluminium closure, aluminium pharmaceutical cap, aluminium cosmetic cap etc; 8011 H14 color coated aluminum foil is normally used for making food container to instead of 3003, and to cover food and wrap food during cooking, and lamination with paper or plastic widely used in various packaging fields.

Alloy:8011 8079

Temper:HO,H18,H14,H24,H16

Thickness:0.15mm-6.0mm

Width:80mm-2300mm

Standard production:ASTM-B-209M,BS EN 485-2,BS EN 573-3,GB/T3880-2008

MOQ:5 tons per size

Mother coil:DC or CC

ID:76mm,152mm,408mm,508mm

Surface:Color coated,many kinds of color

Package:Export standard package with wooden pallet

Package way:Eye to sky or eye to wall

Delivery time:within 30days

Origin:Zhengzhou,China

Certificate: Mill Test Certificate,Certificate of origin:Form A,Form E,CO

Mechanical Properties – 8011 Aluminium Coil Strip

Application

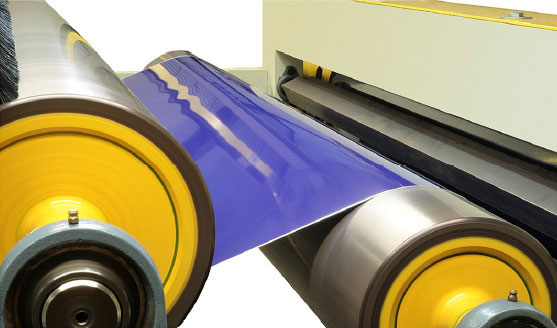

Color Coated Aluminium Strip is widely used in Wall cladding, facades, roofs and canopies, tunnels, column covers or renovations.Interior applications: Wall cladding (lamination), ceilings, bathrooms, kitchens and balconies. Automotive industry, Washing machine cylinder; can body; Can Gellar ring; Ship equipment materials and components; Instrumentation Materials; Building materials and accessories; Sound insulation wall; Electrical machinery assembly such as Maintenance tank, capacitor box, Bearing, TV cabinets,Magnetic disc, Motor frame, container packing, Name plate etc .

According to the use of classification,our Color Coated Aluminium Divided into:

(1) Mirror Finish Coated Aluminium Coil Sheet

(2) PE (Polyester) Coated Aluminum Coil

(3) NAMO PVDF Coated Aluminium Coil Sheet

(4) Brushed Lacquered Aluminium Coils Sheets

(5) Stucco Embossed Finish Coated Aluminium Coil Sheet

(6) Aluminum Powder coated plate for curtain wall

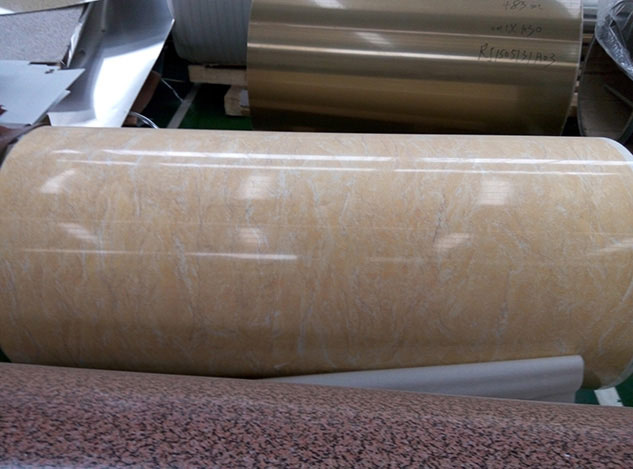

(7) Stone and marble finish Coated Aluminum Coil